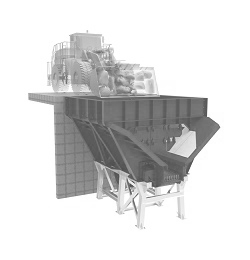

Sludge management from inert washing systems

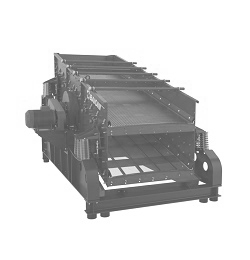

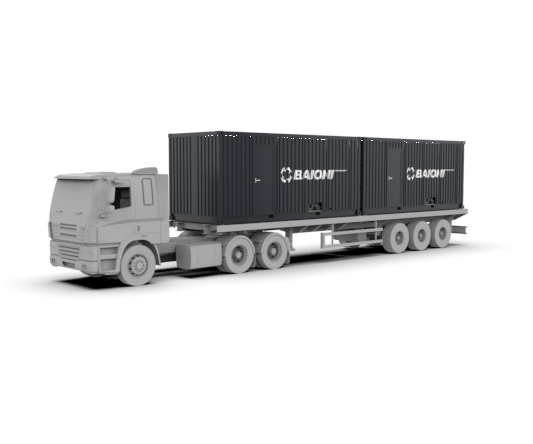

Baioni designs and manufactures horizontal centrifugal extractors to provide excellent performance in the separation of solids into 1 or 2 liquid phases with a single continuous process. They are designed to handle a wide range of fluids, quantities and types of solids. With high efficiency, continuous operation, low cost / performance ratio, low maintenance costs and energy consumption, Baioni decanters are horizontal drum centrifuges to achieve maximum requirements for the extraction of water and sludge from civil and industrial wastewater. Usable in different applications: ecological sector, industrial sector and oil plants. Horizontal centrifuges mod. BaiDec available in mobile and fixed version.

Mining

Quarry

Cementery

Infrastructure

Waste reciclying C&D

Agro-food industry

The principle on which the operation of the decanter centrifuge is based is the difference in specific weight of the materials to be separated.

Such a machine can be considered as a settling tank that rotates around an axis. In the settling tank, the solid particles, heavier than the liquid, move by gravity towards the bottom and form a sediment (solid phase). In a centrifuge, the solid phases and the liquid part are separated by centrifugal acceleration. In the rotating drum, the solid particles, which have a higher density and are therefore heavier than the liquid, move outwards by means of the centrifugal force. The use of the decanter comes when the content of solids in the suspension to be processed is particularly high. This machine has the advantage of guaranteeing high efficiency at the level of clarification and at the level of water extraction, as well as allowing the separation of liquids with simultaneous removal of solids. Key requirements in this field include high drum speed, powerful auger thrust and auger speed that automatically adjusts to the solids loaded into the feed.

- WIDE RANGE OF SOLUTIONS FOR ANY NEED

- AUTOMATIC ADAPTATION DURING OPERATION IN VARIABLE POWER AND OPERATING CONDITIONS VIA PLC OR REMOTE MONITORING

- THE SLUDGE DEHYDRATION PROCESS EXTRACTS GREATER PERCENTAGES OF WATER, SIGNIFICANTLY REDUCING THE MASSES OF DEHYDRATED SLUDGE PRODUCED AND CONSEQUENTLY CONSIDERABLE SAVINGS ON TRANSPORT AND DISPOSAL COSTS